Float valves available in 3/4”, 1’’, 1.5’’, 2’’, 3’’ and 4’’ sizes,

in different float arm and float configurations to suit different troughs and preferences.

Durability

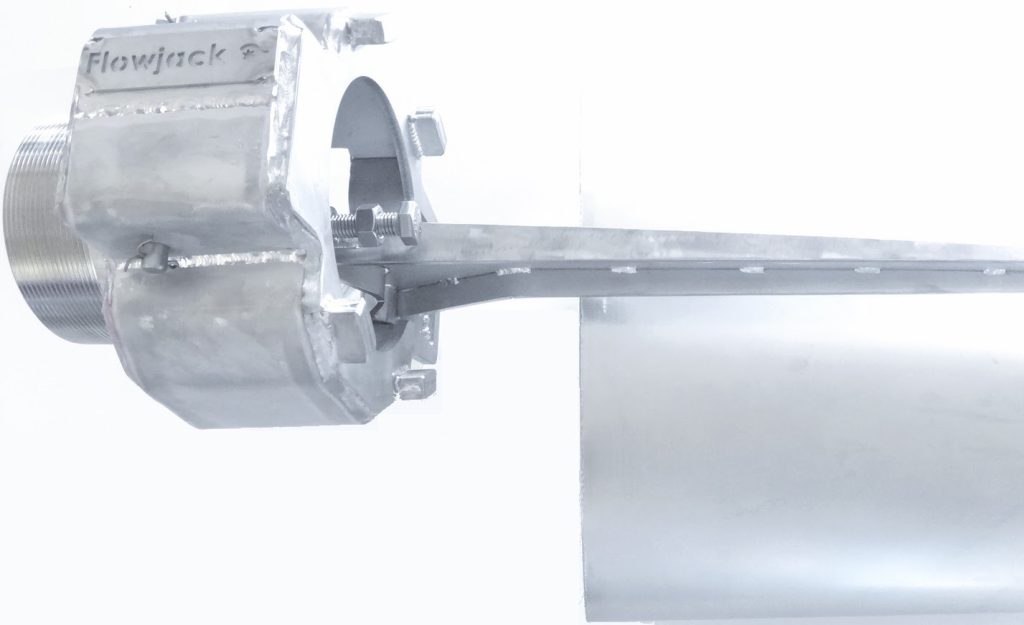

If you don’t have a good cover on your float valve the float arm is the weak link that is likely to be damaged by livestock. The Flowjack flexible float arm resists damage by allowing the float arm to flex rather than permanently bend or break if it is nocked by live stock.

All castings are 316 marine grade stainless steel including the valve seat, ensuring your valve will last a long time. The stainless steel valve seat provides resistance to corrosion and wear at the most critical part of the valve and will not work its way loose under pressure.

Ease of maintenance

A removable float arm pivot pin instead of press fit makes maintenance easy.

High pressure

If you require a valve that can handle high pressure the Flowjack 2 inch high pressure valve is rated up to 112 psi. The Flowjack 1 inch valve is rated up to 249 psi. Please see pressure chart for more details.

Manual shutoff device

- This device is an optional extra that allows the user to override the float valve function and manually shut the valve off so fluid cannot flow through the valve bore;

- This can be a cost effective alternative to purchasing another type of valve to perform this function e.g. ball valve or gate valve;

- Available to suit Flowjack 1’’, 1.5 ‘’, 2’’ and 3 inch valves.

- Click here to watch a video that demonstrate how to install the float valve manual shutoff device.

Reliable design with less trouble & more value

- There are many different types of float valves but in most situations a good quality clapper valve will provide

the least amount of trouble; - The clapper valve design is mechanically simple compared to others which means there is less to go wrong. For example some designs have a sliding piston or sleeve that can become stuck due to a build up of foreign material e.g. grit, calcium and plant matter;

- Many sleeve valves have an O ring as well as the main seal that all float valves have so there are two seals that will eventually need replacing;

- Another plus with the clapper design is the ability to adjust the water height in the trough by simply turning a bolt rather than bending the float arm or adjusting the float chain.

Float valves can be configured with a float arm and float to suit different applications

Please visit the float page for more information.

3/4’’, 1”, 1.5” and 2”Float Valves – Photo Gallery

3/4 inch float valve

1 inch float valve

1 1/2 inch float valve

2 inch float valve

3’’ High or Low Pressure Float Valves – Photo Gallery

4’’ Low Pressure Float Valves – Photo Gallery

The Flowjack 4 inch float valves are also fabricated from 316 marine grade stainless steel and available with rigid float arm.